6 axis robotic arm

Providing host computer source code.

Supporting TTL serial port, wireless serial port, Ethernet, WiFi communication

Support drag teaching

Support joystick control

No control cabinet

ODM and OEM

Description

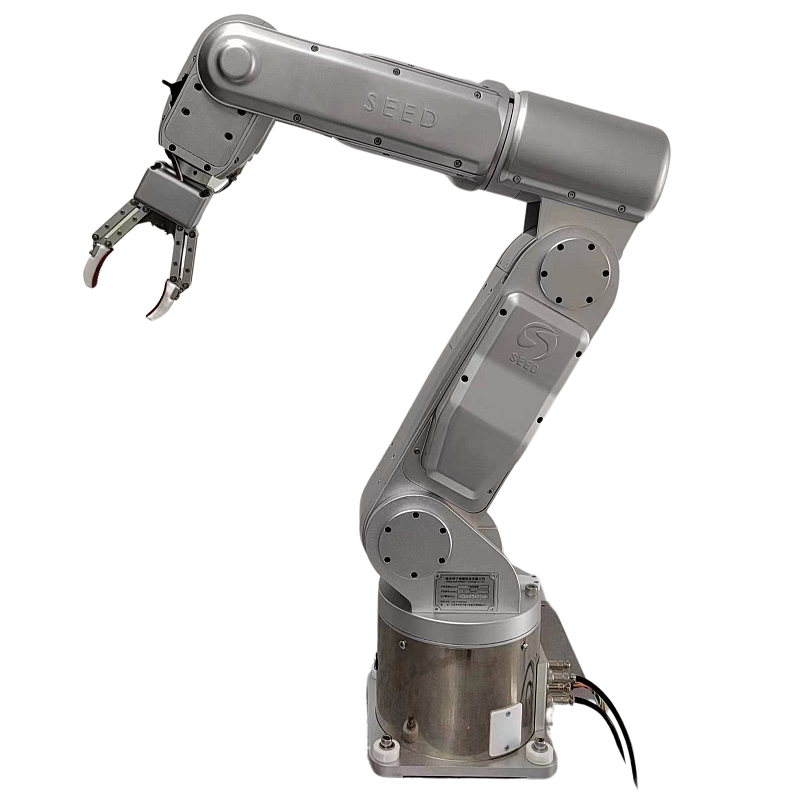

6 axis robotic arm

The Brief Introduction of the Six-axis Robotic Arm

The main function of the 6 axis robotic arm is to move to a series of positions as required and complete certain functions. SEED robot uses serial communication instructions or G code to control the movement of the robot. The end of the robot can be equipped with electronically controlled grippers, suction cups, electromagnets, etc. or special tools to achieve specific functions. In addition, we also designed a joystick teaching pendant to facilitate users’ direct manual remote control and teaching programming.

Some users need to use a computer host computer to send control instructions to make the robot move. For this purpose, we provide a serial communication interface and an open communication protocol. We used C++ Builder 6 to design a general host computer software, providing all source codes to users as templates, which can be quickly modified into user host computer software.

The Brief Introduction of the control function

The serial instruction has a fixed length of 48 bytes and contains all the control and motion functions of the robot. In the 48-byte serial communication instructions, some data uses 4 bytes to represent a floating point number. This part of the data needs to be implemented using the data conversion function in the routine. Please refer to the C source code. Can provide standard TTL serial port, wireless serial port, Ethernet, WiFi communication.

In some cases, people need to remotely control the movement of the robotic arm. In this case, the three-dimensional joystick of the teaching pendant can be used. The joystick control method is consistent with intuition. No training is required, and you can use it flexibly once you get started. If remote wireless control is required, we can provide technical solutions separately.

The programming function of the teach pendant is to control the robotic arm to the target point through the three-dimensional joystick, and then click the touch screen to store the positioning data. It can quickly and accurately program and debug complex path planning without the need for special training. The robot also supports dragging and teaching, and you can directly push the robot to a series of points for recording.

The robotic arm has a programmable switching input and output interface, with 8 input ports and 8 output ports. If a user needs more ports or a photoelectrically isolated input and output controller, it can be expanded as required.

Model | S6H4D-plus |

Number of axes | 6,2 extra axes for optional |

Radius (mm) | 760 |

Range J 1 | ±150º |

Range J 2 | [-65º,110º] |

Range J 3 | ±167º |

Range J 4 | [27º,188º] |

Range J 5 | ±270º |

Range J 6 | [-34º,208º] |

Load Capacity | 3kg, ultimate load 4kg |

Max Speed | Linear 1000mm/s J1&J2: 120º/s, J3&J4: 120º/s, J5&J6:240º/s |

Repeatability | ±0.05mm |

Power | 24VDC/12A,average working current 1.5A |

Total Weight (kg) | 17 |

Body Material | Aluminum Alloy |

Transmission Structure | J1 to J4 with harmonic reducer, J5 with timing belt and spiral bevel gear, J6 with straight gear transmission |

Motor | DC servo motor |

Control Interface | The standard configuration is a ttl serial port, and wireless serial port, Ethernet, and WiFi communication are optional. |

The Specifications of Reducer

Name | Specification |

J1 | 20-50 harmonic |

J2 | 20-50 harmonic |

J3 | 17-50 harmonic |

J4 | 14-50 harmonic |

J5 | gear reduction,Reduction ratio :16 |

J6 | gear reduction,Reduction ratio :12 |

The Specifications of Motor

Name | Specification |

J1 | 200W |

J2 | 200W |

J3 | 100W |

J4 | 50W |

J5 | 50W |

J6 | 50W |

Please Click Here to DOWNLOAD the PDF Manual and related sources .

Please contact us via: forrestxiao26@gmail.com if you have any related question.